CU Hyperloop Wins with TRENDnet at The Boring Company’s Tunnel Boring Competition [CASE STUDY]

October 2024

Traffic and transportation continue to be an issue for cities across the globe. Hyperloop is a concept for a high-speed transportation system designed for both passengers and freight that aims to alleviate traffic congestion. The annual Not-a-Boring Competition aims to challenge teams to come up with new and innovative tunnel solutions that can ultimately be used to develop critical infrastructure to support a massive-scale hyperloop transit system.

The Challenge

The Challenge

CU Hyperloop, a part of the College of Engineering and Applied Science at the University of Colorado Boulder, is a student-led tunnel boring competition team. Each year, students from around the globe compete over eight days in The Boring Company’s annual student tunnel boring competition, Not-a-Boring Competition, in Bastrop, Texas. The competition winner is decided based on the speed and length the team is able to bore a horizontal tunnel.

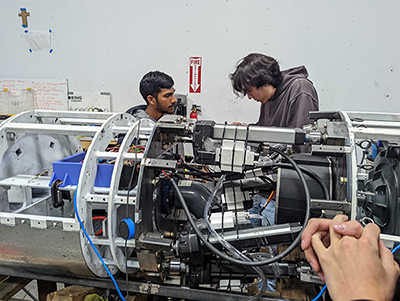

Microcontrollers and microchips on CU Hyperloop’s Tunnel Boring Machine’s (TBM) controlled and moved several parts of the machine, including pushing the machine forward, monitoring temperature, and spinning the cutting head. The CU Hyperloop team needed a rugged solution that would allow the microcontrollers to be networked and communicate with each other throughout the TBM, all while withstanding vibration, debris, and more.

The Solution

The microcontrollers connected to a main computer created a mini-internet that could control the TBM. The microcontrollers and onboard computers were already connected to each other with Ethernet cables. With this in mind, the CU Hyperloop team decided a network switch solution would be ideal.

While many industrial switch companies were considered, CU Hyperloop ultimately decided on TRENDnet’s 6-Port Industrial Gigabit PoE+ DIN-Rail Switch 12 – 56 V, model TI-PG62B, based on a variety of factors, including its ability to handle and work well with the elements, compact size, ease of installation, and variable voltage features with overload current protection.

TRENDnet’s TI-PG62B industrial switch became the center of the TBM’s Ethernet communications and it allowed the team’s software to effectively communicate with the TBM through the dig. The industrial power supplies were incorporated into the TBM’s in-house-built power distribution system, and made testing and integration into the TBM safe and efficient.

TRENDnet’s TI-PG62B industrial switch became the center of the TBM’s Ethernet communications and it allowed the team’s software to effectively communicate with the TBM through the dig. The industrial power supplies were incorporated into the TBM’s in-house-built power distribution system, and made testing and integration into the TBM safe and efficient.

The power distribution system powered both the TBM and the team’s work site, including the emergency stop button in case of mechanical or electrical safety risk. Several tests were run to ensure its workability and reliability. Emergency stoppage functioned consistently when immediate power shutoffs to the TBM were needed.

The Result

“The industrial network switches and power supplies worked great—they were very resistant to the elements and easy to install, power, and set up without taking up too much space. The variable voltage option worked perfectly to step down and convert power from our generator.

“The switches were attached to the back of the TBM during hot, humid Texas days, and dry, below-zero Colorado nights. TRENDnet’s switches were very sturdy and also withstood nearby welding, sparks, and dirt without any failures.

“Our team took second place in the competition this year, and was the top American team. Additionally, the team won the Innovation Award for our inflatable gripper system which anchored the machine underground. TRENDnet's network switches and power supplies have been vital to our team's success.”Zaphod A. Schmidt

CU Hyperloop Team Lead